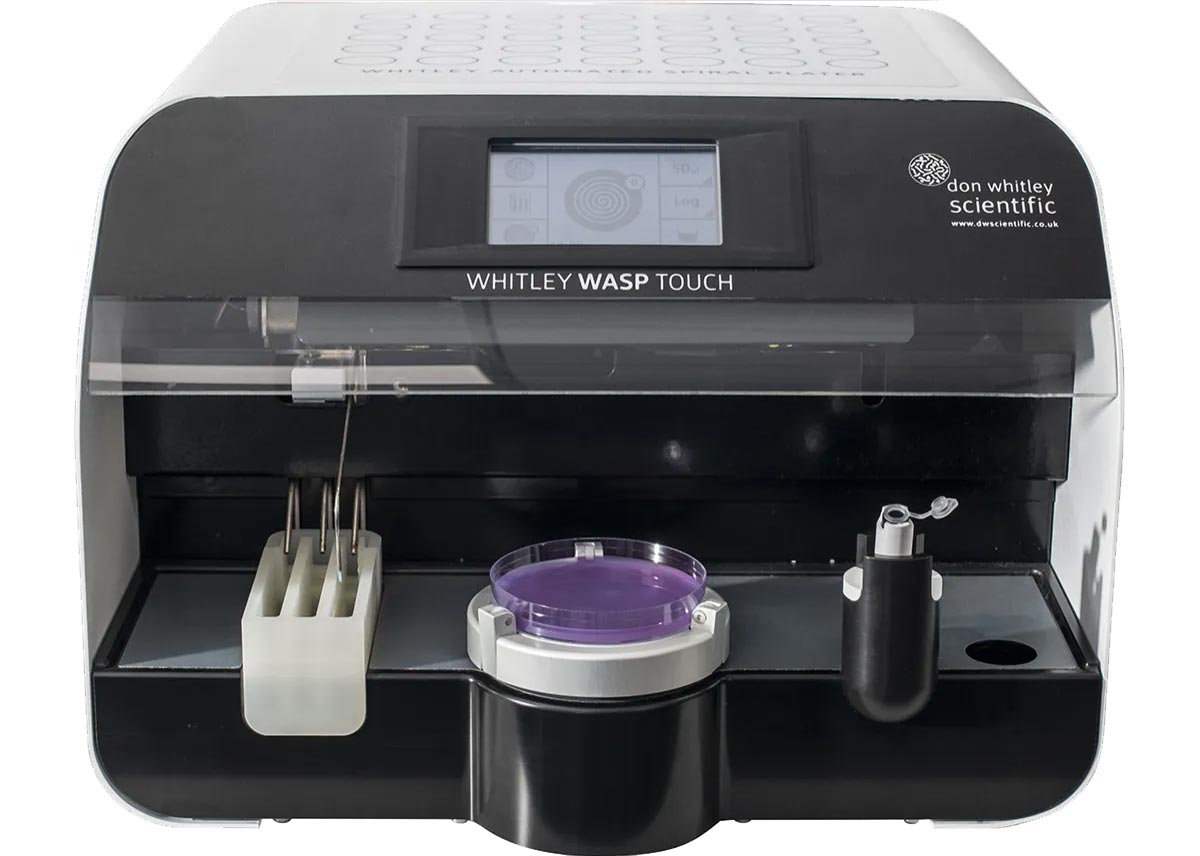

WASP Touch is a new spiral plater, designed for the needs of modern microbiology laboratories. This is a fundamentally different plater with no need for a separate vacuum source. The system is extremely simple to use and provides real cost savings and process improvements. Now it really is time to eliminate serial dilutions!

- Touchscreen operation

- New automatic sanitising system automatically maintains correct liquid levels in sanitising solutions – patent pending

- Illuminated, covered working area

- Robust and reliable

- Easy serviceability

WASP Touch provides Automated Intelligent Monitoring Software (AIMS) to guide you through set-up and daily check routines - ensures consistent trouble-free plating.

- Sample may be aspirated from beakers, bottles and tubes – providing maximum flexibility in use.

- Automatically logs date, time, deposition, user name, number of plates produced – a powerful diagnostic tool.

- Precise quantities of sanitising fluids are dispensed automatically to maintain optimum levels. This ensures effective and efficient sanitisation takes place.

- Sanitising system reservoirs contain sufficient fluid for over 900 wash cycles – perfect for busy laboratories.

- Fully integrated vacuum waste system – occupies the smallest amount of bench width.

- Optional fully comprehensive maintenance and breakdown contracts are available to prolong the life of your investment.

All this and it produces perfect plates!

Options

- Eppendorf Tube

Holder - Use the WASP Touch with Eppendorf Tubes. Only available with the Dilucup WASP Touch Option as this has an altered stylus that allows samples to be collected from a variety of vessels including Eppendorf tubes. An adaptor has been designed that holds both 2ml and 1.5ml Eppendorf tubes along with a further reducing piece to hold a 0.5ml Eppendorf.