With the Inlabtec Serial Diluter it is now possible to mix and dilute a sample in a single step which integrates dispensing and mixing. Major benefits are viable cell counts of highest accuracy combined with a comfortable, intrinsically safe workflow.

Main features of the Serial Diluter:

- Easier, faster and safer sample dilution than with any other method

- Ergonomic and intrinsically safe work process

- Results independent of specific individuals

- Volume checkable before each dispensing

- Directly ready for days

- Compact bench top footprint

- Easy installation and cleaning

- High build quality -

Swiss Made

Swiss Made

Directly visible volume adjustment

Volume setting is straightforward – simply place the sensor alongside the scale of the standard glass or plastic pipette at the required volume. The aspirated volume is checked by a quick look at the meniscus of the liquid and corrected if needed.

The high precision of the optical infrared sensor allows dispensing with a accuracy better than ± 0.6 % for 9 ml.

Direct volume check by the pipette scale - Improved compliance with ISO 6887-1 and ISO 7218Ergonomic design and efficient operation

To start a serial dilution the dosing arm is swiveled forward from its parked position to connect to the 1ml pipette tip containing the sample followed by pressing the start button. The dispensing nozzle remains reliably sterile since during pipetting, the upper part of the pipette tips never comes in contact with the sample and only sterile diluent is dispensed. In the parked position - a protective sleeve protects the dispensing nozzle of the dosing arm against contamination risks. Overnight or over weekend, the dispensing nozzle can also be immersed in 70 % ethanol, which is held in the protective sleeve. As a result the sterility of the system not in use is completely maintained over time and the Serial Diluter is therefore ready in no time if once installed.

- Standardized working process for consistent data quality

- Sterile filters and unidirectional dispensing guarantee the system sterility

- Ready to work over days in no time

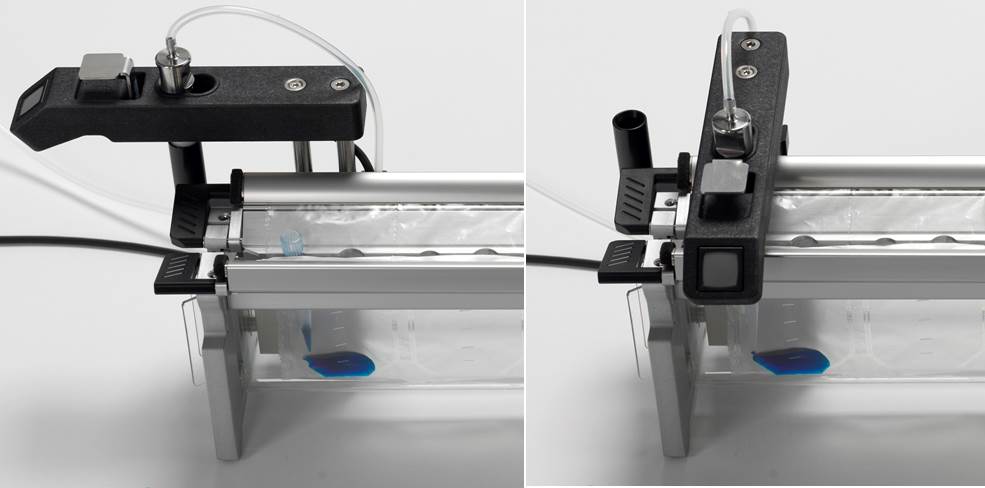

Simple serial dilution bag opening and closing

The side opening of the serial diluter allows quick and easy insertion of up to 6 Serial Dilution Bags. A single, simple hand operation speeds the opening of inserted bags. The grippers handle this task reliably and without wear through the use of van der Waals forces. To facilitate liquid handling - pipette tips are able to directly penetrate through the separate addition and removal ports of the bag.

The defined working process and the position of the dosing arm allow a clear orientation within a dilution series. Therefore no confusions during pipetting can happen, even if you had to stop working unexpectedly for a while.

- Efficient and error-free sample handling

- Wear-free opening of the bags

A pressure sensor monitors the dispensing of the diluent. After the completed delivery of the diluent, a sterile air blast causes a sudden change of the rotational direction of the vortex within the bag. This results in perfect mixing and dilution of the sample eliminating additional manual vortex mixing. As the sample is rinsed out of the pipette tip, the pipetting volume is more accurate and less prone to error.

Dilutions with the Serial Diluter are in accordance with the standard method ISO 6787-1: 1999 and thus meet also the norm ISO 7218: 2007. During the product development phase, extensive series of verifications of the Serial Diluter were carried out by the Zurich University of Applied Sciences (ZHAW), with support from the Commission for Technology and Innovation (CTI).

For the intra-laboratory implementation of the Serial Diluter in accordance with the quality standard ISO 17025:2005 for accredited laboratories, customers have performed comparisons with different food samples such as meat, dairy products, spices, etc. The method was always successfully verified, easily and without problems. A selection of samples analyzed: Sample Selection

- No need for operators to perform manual sample vortexing

- Pipetting independent of specific individuals

- In compliance with ISO 6887-1 and ISO 7218

All mechanical parts of the Inlabtec Serial Diluter, as well as the electronic control system, were developed and are manufactured in Switzerland. The instrument is built according to the highest quality standards and is designed for long reliable operation.

Designed for daily intensive use for years

Minimal benchtop footprint / Easy installation and cleaningThe smart Serial Diluter requires little bench space, a total of something like a vortexer and a test tube rack. Set-up of these easy-to-use instruments is minimal meaning that you are almost instantaneously operational.

The installed serial diluter remains ready for use over several days. The air for blow out of liquids flows through a easily accessible sterile filter and the instrument dispenses only sterile medium via a pipette tip into a Serial Dilution Bags. Therefore, the Serial Diluter never comes in contact with food samples and thus remains reliably sterile, comparable with a bottle of sterile medium vented by a sterile filter.

Permanently active sterile system

Ease of installation for a reliable operation