|

In the laboratory, Memmert incubators are ideal for all applications with temperatures up to +80°C; and for incubating living cultures at +37°C. Thanks to our precise control technology, critical temperature overshoots are impossible, and valuable loads are carefully warmed up. Temperature is increased within a very narrow control range and kept exactly at the setpoint values. Our incubators are available with an adjustable air fan Memmert’s incubators feature a unique sterilization cycle because simply disinfecting the chamber is not reliable. To prevent cross-contamination, the entire incubator chamber, including the ventilation system, water trays and all the sensors can be sterilized with a 4-hour program at 160ºC. The sterilization cycle is only available on Plus models with TwinDISPLAY. Ensuring sterility between loads has never been easier! Temperature deviations caused by fresh air can influence sample characteristics or prolong drying. In Memmert incubators, fresh air is fed through a pre-heating chamber and seamlessly introduced into the working chamber. |

|

|

Standard Features- 8 sizes available: 30 L, 55 L, 75 L , 110 L, 160 L, Incubator IN (with natural convection) and IF (with forced air circulation) are available with SingleDISPLAY. Incubator INplus and IFplus models have TwinDISPLAY. |

SingleDISPLAY Features - Control and display of temperature, program runtime, fan speed, air flap position, and SetpointWAIT function - By activating the SetpointWAIT function, the process time does not start before the set temperature is reached at all measuring points, including the optional freely positionable PT100 sensors inside the chamber or load. - Ethernet connection at rear of incubator

|

TwinDISPLAY Features - All the functions of the SingleDISPLAY but also controls and displays device specific parameters such as humidity as well as graphical display of the program sequence. - AutoSAFETY integrated temperature monitoring system. AutoSAFETY can be activated to automatically follow the set temperature with a freely selectable tolerance. Individual MIN/MAX values can be set for over/under temperature. - HeatBALANCE function for application specific adjustment of heating power distribution between the upper and lower heating groups in an adjustment range of -50% to +50%. - USB port for uploading programs, downloading protocol logs and activating the User-ID function - Fan speed monitoring (optional) |

|

|

|

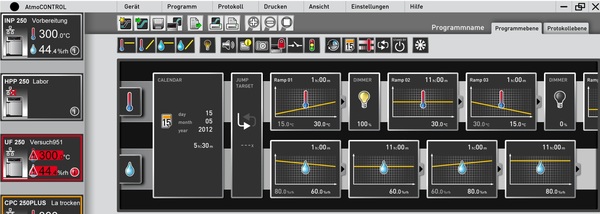

AtmoCONTROL Software AtmoCONTROL software is the newly developed control and logging software for all Memmert Generation 2012 incubators. Simply drag and drop the graphical symbol for the desired parameters to the input field and change the values according to your application. AtmoCONTROL allows users to save the log files in various formats. All TwinDISPLAY incubators are supplied with AtmoCONTROL software on a USB drive. All SingleDISPLAY incubators come with a 90-day test version. The full version can then be purchased if desired. |

|

Specs

| Model Sizes/Description | 30 | 55 | 75 | 110 | 160 | 260 | 450 | 750 | ||

| Stainless Steel Interior | Volume | approx. l | 32 | 53 | 74 | 108 | 161 | 256 | 449 | 749 |

| Width | mm | 400 | 400 | 400 | 560 | 560 | 640 | 1040 | 1040 | |

| Height | mm | 320 | 400 | 560 | 480 | 720 | 800 | 720 | 1200 | |

| Depth (less 39mm for fan) | mm | 250 | 330 | 330 | 400 | 400 | 500 | 500 | 600 | |

| Stainless Steel Grids (standard equipment) | number | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Max number of grids | number | 3 | 4 | 6 | 5 | 8 | 9 | 8 | 14 | |

| Max loading per grid | kg | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |

| Max loading of chamber | kg | 60 | 80 | 120 | 175 | 210 | 300 | 300 | 300 | |

| Textured Stainless Steel exterior | Width | mm | 585 | 585 | 585 | 745 | 745 | 824 | 1224 | 1224 |

| Height (size 450, 750 with castors) | mm | 707 | 787 | 947 | 867 | 1107 | 1186 | 1247 | 1726 | |

| Depth (with door handle), door handle + 56mm | mm | 434 | 514 | 514 | 584 | 584 | 684 | 784 | 784 | |

| Further Data | Power consumption at 230V / 115V, 50/60Hz | ~ W | 800 | 1000 | 1250 | 1400 | 1600 | 1700 | 1800 | 2000 |

| Working temperature range | °C | min. 5K(IN/IN Plus) 10K(IF/IF Plus) above ambient temperature up to +80 °C |

||||||||

| Setting temperature range | °C | +20 to +80 | ||||||||

| Setting Accuracy | K | 0.1 | ||||||||

| Packing Data | Net weight | approx kg | 44 | 55 | 64 | 72 | 80 | 96 | 160 | 192 |

| Gross weight (packed in carton) | approx kg | 55 | 67 | 76 | 86 | 96 | 114 | 185 | 242 | |

| Width | ~cm | 69 | 70 | 70 | 83 | 83 | 93 | 134 | 134 | |

| Height | ~cm | 86 | 94 | 111 | 104 | 127 | 134 | 141 | 189 | |

| Depth | ~cm | 66 | 73 | 73 | 79 | 79 | 89 | 99 | 99 | |

Options & Accessories

Entry Port 23 mm diameter for introducing connections at the side, can be closed by flap and silicone stopper. Standard positions: Left center, left top, right center, right top

Other port Available in 23 mm, can be closed by flap. Can be located on left side, right side or rear of unit

Other port Available in 14 mm, 38 mm, 57 mm, 100 mm and 120 mm diameter. Can be closed by flap, located on rear of unit

Additional PT100 Temperature probe Can be positioned flexibly in chamber or load, for local temperature measurement. (max. 1 for SingleDISPLAY units, max. 3 for TwinDISPLAY units)

Interior Lighting 15 W for sizes 30-260 L, 2 x 15 W for 450 and 750 L sizes

Interior Socket Interior socket can only be ordered with limited temperature range up to max. +70ºC

Perforated stainless steel shelves Full width

Additional stainless steel grids (racks) Full width

Stainless steel tray Non-perforated, 15 mm rim, may affect temperature distribution

Bottom drip tray May affect temperature distribution

Wall Bracket Tubular frame for wall mounting

Calibration certificate for 3 temperatures +37ºC, +52ºC and +70ºC

Fan speed monitoring Optional, only for IFplus models

IQ/OQ Services Available Please contact us to discuss your validation needs

4-20 mA current loop interface (0-90ºC corresponds to 4-20 mA) Temperature controller actual value; temperature of a PT100 sensor positioned flexibly in chamber