Select size range

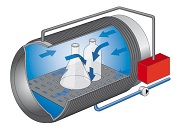

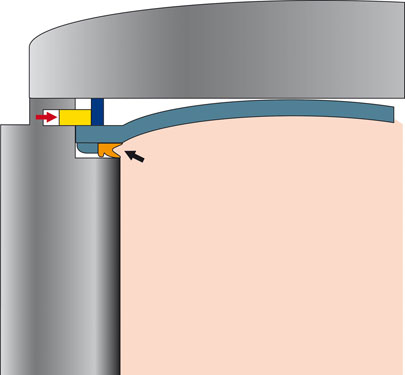

Innovative automatic safety door lock

Easy and safe. When the autoclave lid is closed, the lid is automatically locked by a circumferential ring system. A special lip seal made of heat resistant silicone provides reliable sealing. As steam pressure builds within the sterilizer, the seal becomes tighter.

The lid also opens easily – either at the push of a button or automatically at the end of a sterilization cycle.

The door-locking system on this double door autoclave, is temperature dependent and adheres to national and international safety standards. The door remains locked as long as there is excess pressure in the chamber. The lid, like other parts of the pressure vessel and housing, is made of stainless steel. The modern design faceplate, which also contains the control panel, display and part of the control technology, is made of heat resistant and insulated plastic. There is no risk of the autoclave operator coming into contact with hot components.

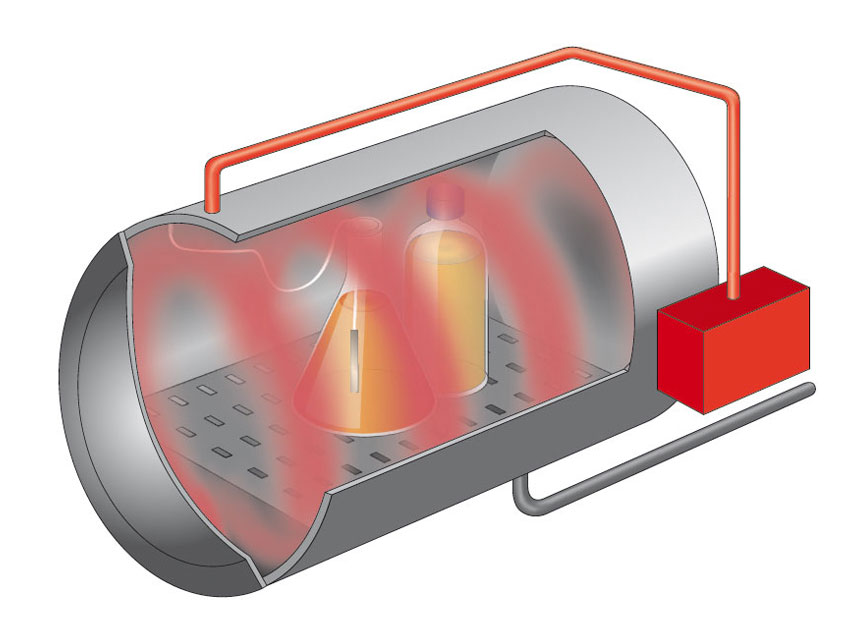

Steam generation

A steam generator is incorporated in the sterilizer housing providing substantial benefits:

- No heating elements and no reservoir for dirty water in the chamber

- With stand-by pre-heating option, only 10 min. heating time to 121° C with an empty chamber

- Improved removal of air from the empty chamber via pulsed heating (rapid attainment of optimal steam atmosphere, even without a vacuum)

- Accuracy better than ± 0.5° C with empty chamber

- Quicker cooling as neither the hot water in the chamber nor the separate steam generator need to be cooled

- After cooling, steam is immediately available for the next sterilization run.

Condensation of steam instead of removal

Exhaust steam is condensed automatically via a PT-100-regulated cooling system. This prevents odors and protects waste water piping that may be made of plastic.

Pressure-safe up to 5 bar/150 °C

The Systec D2D-Series double door autoclave units are the first of its kind to be designed for higher pressures and temperatures. The standard pressure sterilizer chamber is designed for 5 bar/150 °C. If the expanded pressure and temperature model is selected as an option, all control and safety components are adapted to the higher temperature and pressure. This option may be retrofitted to existing pass through autoclave units.

Systec pass through autoclave units are equipped direct from the factory for sterilization temperatures up to 140 °C and 4 bar of pressure.

Quality materials quality manufacturing

The pressure vessel of the autoclave is made of corrosion-resistant stainless steel 1.4404 (AISI 316L). The double door autoclave framework and housing are also made of stainless steel. The highly efficient, high-quality Hanno-Tect insulation material releases no particles and therefore the Systec D2D-Series sterilizer is ideal for use in clean room environments

Exhaust steam is condensed automatically via a PT 100-regulated cooling system. This prevents odors and protects waste water piping.

Operation by Touch-Screen technology

Operation is easy and rapid via a large (5.7 inch) touch screen interface for direct reading. This innovation oers additional options and increased flexibility when working with the autoclave. For example, process data can be displayed numerically or graphically. 7 programs are pre-defined but can be expanded (up to 100) as required by the user. To create a new program, the user is guided through the process by a menu dialog. Every new program is automatically assigned to a permanent, unalterable name and can also be given an individual designation by the user. All process parameters can be individually altered.

Pre-defined programs

- Solids

- Waste bags

- Liquid waste

- Liquids

- Cleaning

- Vacuum test*

- Bowie-Dick test*