Select size range

Systec Autoclaves Give You Data Control and Documentation

Your advanced Systec autoclave stores cycle data that can be downloaded from the autoclave, or transferred directly to your network via FTP as PDF and/or CSV (Excel) files. Both documents are electronically signed by the autoclave. This electronic signature is unique and specific to each autoclave. Manual manipulation of any data will result in the file being marked as invalid.

The advanced 21 CFR Part 11 solution includes:

- Extended user account control with customizable access, group assignments and more.

- AuditTrail: all executed actions are documented and can be traced back to the respective user and time stamp

- There are up to five fields for electronic signatures

Communication Options:

- FTP – data can be automatically sent to the server or PC at the end of the autoclave cycle

- Systec Connect DS – Optional app that can be installed on PC, tablet or smartphone. Allows for viewing of real time data and archiving after cycle completion. Systec Connect DS requires no installation to the customer’s network

- OPC-UA – Transfer of data in real time to a SCADA or LIMS

- USB – Standard on all systems for transfer of PDF cycle runs

- Printer – Optional printer that will print cycle data

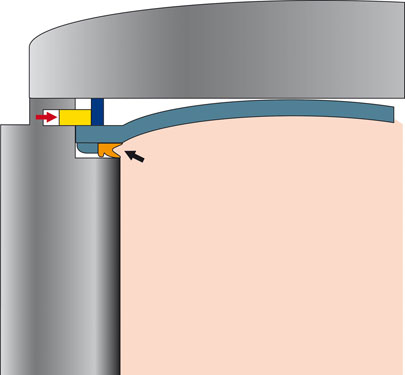

Innovative automatic safety door lock

Easy and safe. When the autoclave lid is closed, the lid is automatically locked by a circumferential ring system. A special lip seal made of heat resistant silicone provides reliable sealing. As steam pressure builds within the sterilizer, the seal becomes tighter.

The lid also opens easily – either at the push of a button or automatically at the end of a sterilization cycle.

The door-locking system on this high capacity autoclave, is temperature dependent and adheres to national and international safety standards. The door remains locked as long as there is excess pressure in the chamber. The lid, like other parts of the pressure vessel and housing, is made of stainless steel. The modern design faceplate, which also contains the control panel, display and part of the control technology, is made of heat resistant and insulated plastic. There is no risk of the autoclave operator coming into contact with hot components.

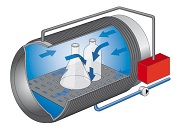

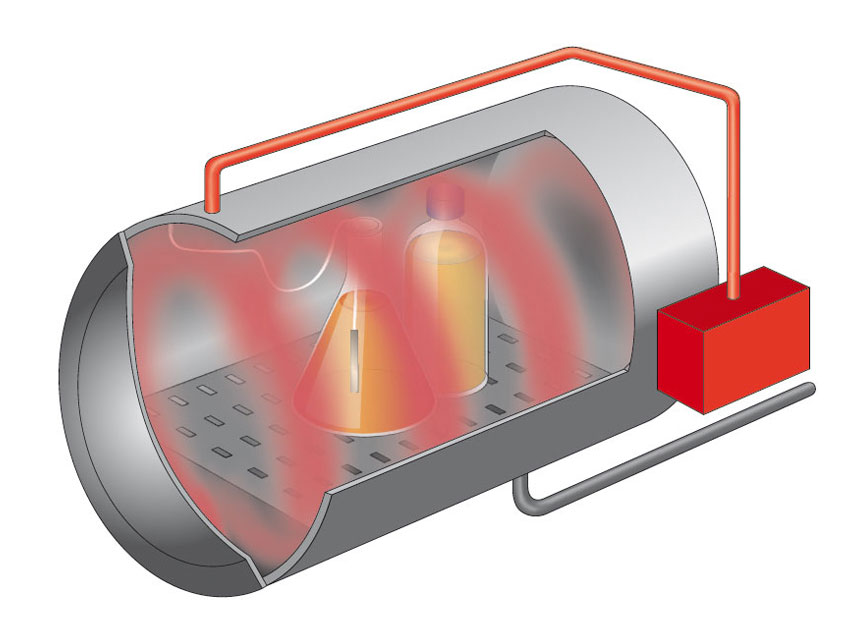

Steam generation

A steam generator is incorporated in the sterilizer housing providing substantial benefits:

- No heating elements and no reservoir for dirty water in the chamber

- With stand-by pre-heating option, only 10 min. heating time to 121° C with an empty chamber

- Improved removal of air from the empty chamber via pulsed heating (rapid attainment of optimal steam atmosphere, even without a vacuum)

- Accuracy better than ± 0.5° C with empty chamber

- Quicker cooling as neither the hot water in the chamber nor the separate steam generator need to be cooled

- After cooling, steam is immediately available for the next sterilization run.

Pressure-safe up to 5 bar/150 °C

The Systec H-Series high capcity autoclave units are the first of its kind to be designed for higher pressures and temperatures. The standard pressure sterilizer chamber is designed for 5 bar/150 °C. If the expanded pressure and temperature model is selected as an option, all control and safety components are adapted to the higher temperature and pressure. This option may be retrofitted to existing H-series horizontal floor standing autoclave units.

Systec H-Series high capcity autoclaves are equipped direct from the factory for sterilization temperatures up to 140 °C and 4 bar of pressure.

Quality materials quality manufacturing

The pressure vessel is made of corrosion-resistant electro-polished stainless steel 1.4571 (V4A) AISI 316 Ti and therefore very easy to clean. The large capacity autoclave framework and housing are also made of stainless steel. The highly efficient, high-quality Hanno-Tect insulation material releases no particles and therefore the Systec HX-Series sterilizer is ideal for use in clean room environments

Exhaust steam is condensed automatically via a PT 100-regulated cooling system. This prevents odors and protects waste water piping.

Controls – new generation

The Systec high capacity autoclaves have a “comprehensive intelligence”: Pressure is controlled via an electronic pressure transducer. Additionally, there is a flexible temperature sensor in the sterilization chamber or in a reference vessel (for liquids) and another sensor at the coldest part of the chamber, the condensate outlet. The microprocessor, specially developed for our laboratory autoclave, controls all relevant functions such as steam pressure, temperature and sterilization time as well as optional rapid cooling, pre / post-vacuum and drying.

Menu-presented instructions in easy to read text form. An advanced touch screen with acoustic confirmation signal. Ergonomically located in a logical and easy to operate position.